Your Cart is Empty

Free shipping for orders $150+ | Seamless returns | Price match guarantee

Written by Ali Mirza (@alitxtile)

With the release of Pure Blue Japan’s game-changing 17.5oz. Aizome denim a few months ago, the return of Studio D’artisan’s stunning 15oz. Aizome jeans this Fall—after a three year hiatus no less—, and Fullcount’s 13oz Aizome in the 1101 cut, this looks to be the year of Aizome for all weights and seasons.

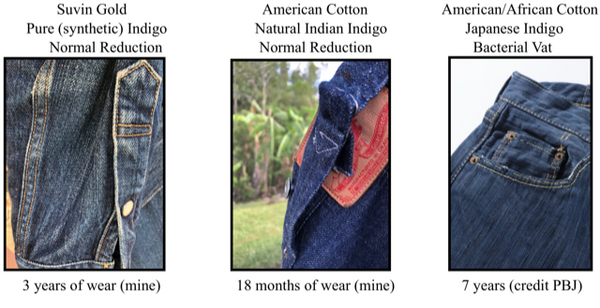

My appreciation for how much goes into the production of Aizome fabric and jeans has only risen as I’ve learned about this incredible fabric. So I wanted to share some about what makes Aizome so special. Note, of course, that I write this as an observer and certainly not an expert on Aizome—but given that there is not much direct discussion about what in particular separates Aizome from other fabrics I thought this is a conversation worth having and, hopefully, a topic worth learning about more together. There are three quite different kinds of categories of indigo denim that I’d like to discuss in this article, examples of which are below (middle photo is mine with the first and third from Okayama Denim):

To better appreciate the differences in these let us start out with some interesting features about the molecule at the center of this story: indigo!

Indigo Dyeing

Indigo is arguably the most significant molecule in human history in so far as textiles are concerned. It is highly lightfast meaning that we can work out in the sun for years and yet indigo will not fade. It is also, relative to many natural dyes, wash-fast as it is not soluble in water. Indigo protects the fabric from light degradation, microbes, and gives fabrics a gorgeous blue-ish color not commonly found in nature.

To better understand what Aizome is and how it differs from other indigo dyeing it first helps to differentiate between two things about indigo: its source and its reduction.

The source of indigo is, largely, where it comes from. Traditionally, indigo used to be derived from plants such as India’s Indigofera tinctorium and Japan’s Polygonum tinctorium. After the 19th century, however, it has become possible to derive indigo synthetically from petroleum which results in a non-plant derived indigo—called both synthetic and pure indigo. As most in the raw-denim community are aware, denim is usually classified as simply indigo or specified to be “natural indigo” which means that it is dyed using indigo derived from plants. This is only the tip of the iceberg of indigo dyeing and to better appreciate Aizome we need to look at reduction first.

The reduction of indigo refers to a necessary step in dyeing that involves making indigo water-soluble so that it can penetrate the fibers involved such as cotton or wool. The way that Aizome involves reduction seems almost magical at times, so I hope it is acceptable to just get a tiny bit technical for a second and then we’ll come back around to Aizome.

The main problem with indigo dyeing, and what makes indigo so resilient on the fabric, is that it is not soluble in water, it is largely hydrophobic. This is true of both synthetic and natural indigo. Attempting to dissolve either in water just leads to a powdery mess which won’t cling or stick to, in our case, the cotton threads. The water will make the threads wet but because the indigo and water do not like each other the indigo will not come with the water and enter the yarn.

So, before any sort of dyeing can occur with any sort of indigo, we need to find a way to get indigo and water to bond together so that the water can “carry” the indigo molecule deep into the cotton yarn. To do this, there has to be some sort of way to tempt the water into wanting to engage with the indigo molecule and vice versa. Water, being H2O, is a polar molecular with the hydrogen end of water having a slight positive charge and the oxygen end having a slight negative charge.

Indigo, on the other hand, is not polar. So to get the water to work with the indigo molecule, we need to give the indigo something that will draw the water towards it. Since the hydrogen end of water molecules is positive, we can try to create a chemical reaction in which indigo receives a negative charge somewhere on it (in this case the oxygen portion of indigo). If we can do this we will turn the indigo into Leuco-indigo which looks like this:

Notice the extra “negative” on the Oxygen in the Leuco-indigo. Because of this negative charge, water and indigo have something to offer each other and willing to work together—opposites attract.

But how can we convert indigo into leuco indigo? The standard and most common way to do this to use a chemical such as sodium dithionite (as seen in the figure above) which will covert indigo into leuco indigo. Sodium dithionite can be used on both synthetic indigo and indigo derived from plants but does not lead to Aizome. This is where we can distinguish between three sorts of indigo fabrics commonly found in Japan:

This corresponds to the categories listed at the beginning of this article. Note that the natural indigo that is directly chemically reduced (Category 2) usually comes from leaves from India while the leaves for Aizome dyeing in Japan have to come from Japan too (more on this in a second).

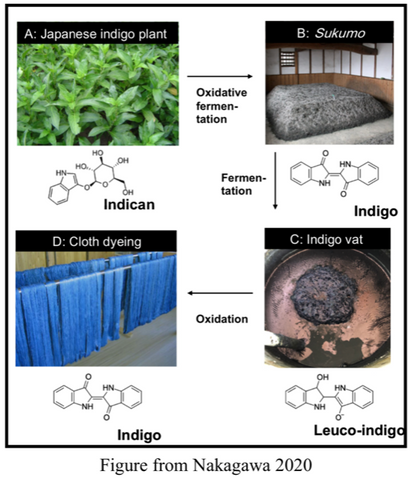

Now we can get to the meat of the matter. What separates Aizome is that it does not use a direct chemical agent, like sodium dithionite, to “add” the electrons onto the indigo molecule. Instead, Aizome involves creating a “living” vat of bacteria which convert the indigo into the leuco indigo using means scientists still haven’t fully explained—this is how indigo had to be reduced prior to modern methods! The processes involved here are fascinating. The following figure from Nakagawa et al (2020) is a great place to start. We’ll start with what happens after the plants have been grown and cut in (Stage A):

Stage B:

The process starts by first cutting and creating a compost of sorts of the Japanese indigo plant, Polygonum tinctorium. As Nakagawa et al describe it:

The leaves are harvested and air-dried. Then, approximately three tons of dried leaves are mixed with the same amount of water and stacked to ca. 1 m in height. Once every 2 to 3 days, the leaves are mixed up and down with water for sufficient aeration (oxidative fermentation). The temperature reaches about 60°C due to the fermentation heat during the plant tissue decomposition. The microbial oxidative fermentation of the leaves proceeds under aerobic conditions and at an appropriate temperature with the sophisticated techniques of trained craftsmen. This operation takes up to 100 days to produce composted and fermented product called sukumo. The second fermentation process proceeds with sukumo in Aizome tanks that have been developed in Tokushima Prefecture, Shikoku, Japan. (Nakagawa 2020)

The leaves themselves contained indican which, via oxidative fermentation, is turned into indigo. We can see why the production of the sukumo is necessary as Aino et al write that:

The production of sukumo, the composted Japanese indigo plant, was developed not only for the preservation and transportation of indigo dye but also for enrichment of the indigo dye in the plant. In addition, the remaining microorganisms serve as inocula for the culture in next fermentation step, and the microorganisms present in sukumo can survive for at least 5 years. Furthermore, the remaining plant materials can be used as nutrient sources for microbial growth in the next fermentation step and may aid the attachment of the essential microorganisms to the debris. (Aino et al. 2018)

So the cultivation and production of the sukumo seems to prepare the leaves with the right sort of bacterial communities for the next stage, the Aizome vat, whilst converting the indican in the leaves into indigo.

Stage C (The Vat):

As we saw earlier, getting indigo is only the start of our story. To make the indigo water-soluble we need to reduce the indigo. The Aizome vat contains the microbial communities that are necessary for this to happen. So for the next stage:

First, sukumo is wetted with hot wood ash extract (80°C) and mixed well in a container. The obtained clay-like product is subsequently kneaded well, added to a small amount of Japanese rice wine, and allowed to settle overnight at room temperature. Next, hot wood ash extract is added at up to one-third of the final volume. After indigo reduction occurs, fermentation liquid is added at up to two-thirds of the final volume. (Aino 2018)

At this point, the Aizome vat, because it is living, has to be fed and taken care of. Because of this, the bacterial communities have to be fed a number of items like sake, wood ash extract, lime, and even wheat. As the Aizome vat thrives and changes, Aino et al (2018) write:

[t]he microbiota, including indigo-reducing bacteria, was continuously replaced with other microbial communities that consisted of other types of indigo-reducing bacteria.

They add that:

Although more than 10 species of indigo-reducing bacteria were identified, the reduction mechanism of indigo particle is riddle.” The Aizome vat does not contain only a single bacterial species but a a diverse community of many species which changes as the vat is fed and reaches maturity.

Even in 2021, scientific analysis still struggles, despite progress, in understanding this method of fermentation with Nakagawa et al writing that:

The fermenting dye suspensions in which the indigo reduction takes place are highly complex regarding nutrients and microbial organisms, and thus the mechanism and the electron donor of the microbial indigo reduction in such environments remains unclear for long. (Nagakawa 2020)

Much remains to be understood about how bacteria can convert indigo and what enzymes they use. More importantly, it is still not clear how the different steps involved in the process described above harmonize into a living vat that can be used for such a rich dyeing process.

Stage D:

Once the vat is mature and ready for dyeing, even here Aizome differentiates itself. Rather than being rope-dyed which leads to fading, Aizome is hand-dyed with the cotton threads dipped by hand into the fermentation vats where the bacteria-reduced indigo penetrates the yarn in the watery liquid.

From here, the leuco-indigo in the vats has to be converted back to gorgeous indigo and to do the craftsmen must aerate the yarns in the air after every deep soak to remove the negative charge from the leuco-indigo, turning it into indigo, using the oxygen in the air to do so. In the images below, taken by Merv Sethi, you can see how the oxidation of the leuco-indigo, after a rinse, leads to indigo’s famous hue.

Doing this over and over up to 20 times leads to the deepest indigo hues, turning the cotton into the legendary yarns that make up Aizome. Even the final stage of making Aizome fabric is different in that looms used to make the selvedge denim are present in-house in Tokushima. The weaving process itself could be given a write-up of its own!

From the growing of the plants in Japan to the living organisms that make the Aizome sukumo and the Aizome vat, to the hand-dyeing of the yarns, and to the weaving of the denim, Aizome is a symphony of plant, bacteria, and human working together to form a fabric.

Reflections on the Different Indigos

It should also be noted that because the Aizome vat is fed with wine, wheat bran, and hot ash extract and the sukumo includes pieces of dirt and parts of leaves the resulting color is not pure indigo blue but a mix of shades and hues. This lends the Aizome fabric a softer shade with more variation internal to it. What is lovely about these processes, of course, is just how many different denims we now have access to. The eternal blue of the Aizome is impossible to recreate with other means but so is the high-contrast fades of rope-dyed synthetic indigo and the softer but still fading characteristics of rope-dyed natural indigo. All are unique with their own beautiful characteristics. Add to that the different feels of denim from different brands, from PBJ’s slub to Studio D’artisan’s suppleness and hairiness, and it is clear that we have a kaleidoscope of colors and textures to experiment with.

In my limited experience, my SDA Suvin Gold shirt and Pure Blue Japan pure indigo (both synthetic) jeans have faded quite quickly and every time I wash them the fabric is waiting to bleed exposing areas of underlying white cotton. On my natural indigo TCB Jeans, using Indian indigo leaves and rope-dyed 8 times, the indigo has a stickier feel but also a more softer more iridescent hue.

My personal favorite shade of indigo is the one intermediate between its starting purplish hue and the entirely faded one where the white cotton begins to show—a mid ocean blue. The pure, synthetic indigo’s start off more purplish but then reach this ocean blue stage quicker while the natural indigo, especially the Aizome seem to sit in this sweet spot longer. All three tease 50 shades of blue in their own ways.

Ultimately, the manner of dyeing such as number of dips, how it is oxidized, the cotton used, and the character of the fabric have as much to contribute to the look at whether it is natural or synthetic or Aizome. What is obvious though is that all of these different methods lead to denims with entirely different spirits and characteristics.

Life would be boring if we were all the same and the same goes for denim. My hope here was to help present how Aizome has an appeal of its own in just how many processes are involved in it as well as the aesthetics the deep blue fabric lends itself to. I hope that all the categories of denim from synthetic to natural indigo, from bacterial reduction to direct chemical reduction, from rope-dyeing to hank-dyeing will be present in the future for many generations to experience.

Conclusion

What makes Aizome so special is just how many living things participate in its production. The plant leaves produce the indican which is then handed to the living bacteria who have to be kept happy via offerings of sake, wheat bran, and wood-ash extract as the indican is converted into indigo and leuco-indigo. The bacteria then hand off the reduced indigo in yarns to the artisans who convert it back to the purple-blue hue by imbuing the yarns with the fresh Tokushima air. Aizome involves many living things each different from each other working together to make a gorgeous fabric, and our scientific attempts are only now beginning to understand how this occurs. In order for us to learn about this human-plant-microbe interaction, fermentation methods like Aizome as practiced in Japan as well as variants of this practiced in India and other areas of the world are so worth protecting and cultivating—knowing how to keep the bacterial vat happy and producing and converting indigo is tremendously difficult and an art-form that should not be lost to time.

The amount of effort put into the fabric by the plants, the sukumo, the living vat, and the artisans means that Aizome should be treasured as both art form and fabric. This is why, for me, I have begun to not only appreciate but celebrate that Aizome. Aizome is as “living” a fabric as we can possibly produce and the inclusion of the sake, the what bran, and the wood-ash colors and softens the indigo into something quite distinct. The fact that Aizome fades differently and with a gorgeous subtlety in comparison to many of the also wonderful denims listed in Category 1 and 2 is part of its appeal and charm—the hank-dyed Aizome indigo seeped deep into the cotton yarns, representing the hard work of the plants, bacteria, and artisans, should be there in its ocean blue hue for all to appreciate decades from now.

----------------------------------------------------------------------------------------------

Aino, Keiichi, Kikue Hirota, Takahiro Okamoto, Zhihao Tu, Hidetoshi Matsuyama, and Isao Yumoto. "Microbial communities associated with indigo fermentation that thrive in anaerobic alkaline environments." Frontiers in microbiology 9 (2018): 2196.

Buscio, Valentina, Martí Crespi, and Carmen Gutiérrez-Bouzán. "A critical comparison of methods for the analysis of indigo in dyeing liquors and effluents." Materials 7, no. 9 (2014): 6184-6193.

Nakagawa, Kasumi, Michiki Takeuchi, Mayu Kikuchi, Suzuna Kiyofuji, Masami Kugo, Takaiku Sakamoto, Kenji Kano, Jun Ogawa, and Eiji Sakuradani. "Mechanistic Insights into Indigo Reduction in Indigo Fermentation: A Voltammetric Study." Electrochemistry (2020): 20-00123.

Saint Mary’s Physics Demos. Halifax, NS. Accessed: 05/30/2021. Link: See: https://demos.smu.ca/index.php?option=com_content&view=article&id=173&Itemid=85